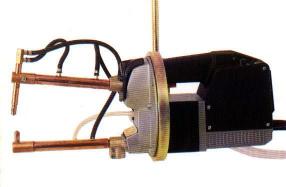

LORS/TECNA

| SELF-CONTAINED SQUEEZE TYPE RESISTANCE SPOTWELDER FOR UNIBODY REPAIR WELDING |

| Model 5048A for repair welding of unibodies in compliance with automakers’ approved repair procedures. |

|

|

SPECIFICATIONS

| WELDING CAPACITY-Maximum on mild steel 5″ arm length / Sheet – 2 x 13 ga. / Round – 2 x ¼” diameter | ||

| WELDING RATES (using shortest optimum weld times and maximum optimum weld current to make consistant strong welds.) |

2 x 26 ga. – 600 welds/hour | 2 x 18 ga. – 200 welds/hour |

| 2 x 22 ga. – 380 welds/hour | 2 x 16 ga. – 120 welds/hour | |

| 2 x 20 ga. – 280 welds/hour | 2 x 13 ga. – Intermittent | |

| TRANSFORMER RATING: 2.5 KVA @ 50% duty cycle MAXIMUM SECONDARY WELDING CURRENT: 9000 amps SC ELECTRICAL CONNECTIONS: 220 volts, single phase CABLE: (max 5% voltage 65ft.) #8 AWG FUSE SIZE: 25 amp long delay type |

WELDER CONTROL: Internal to gun WELD TIME: Solid state NEMA type 1-A capable of ½ second or less weld times for welding automotive HSS, HSLA and mild steels. Adjustable 2 to 90 Hz (1/3 second to 1½ seconds. Repeatable accuracy ± 1 Hz (1/60 sec.) WELD HEAT: Solid-state phase shift, stepless adjustment 30% to 100% for correct weld current selection with long reach or wide gap arm sets |

|

|

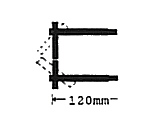

Arm Set Part #7507 Tight clearance arms for pinch weld areas and quarter panels. |

Arm Set Part #7528 Swivel tip, used for minimum marking on door skins. Use with set part #7501. |

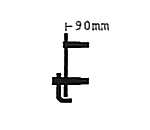

Arm Set Part #7501 General purpose use. Exposed pinch weld areas. Radiator supports, door openings and skins. |

Arm Set Part #7510 For fender wells and other flanges. |

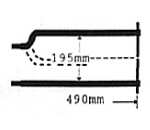

Arm Set Part # 7518 Long reach arms. For floor pan and quarter panel.

|