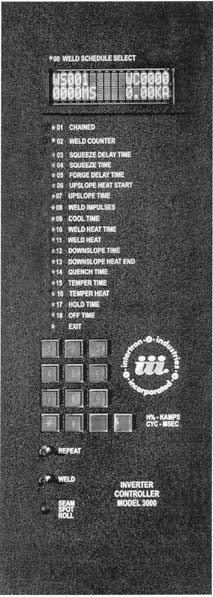

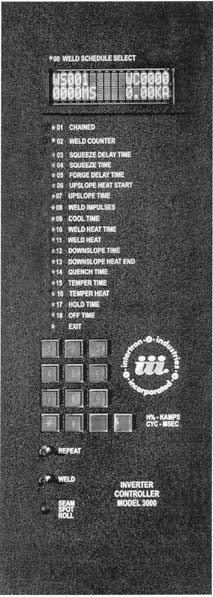

Medium Frequency Inverter Resistance Welding Controller

FEATURES AND SPECIFICATIONS

• Spot Weld – Seam Weld – Roll Spot Weld – Butt Weld

• Fully Programmable 999 Weld Schedules

• Programmable Weld Counter for Each Weld Schedule

• Primary Weld Current Limit Built in Monitor

• Secondary Current Monitor with Auto Scaling 1K Amps to 99K Amps

• Welding Transformer/Rectifier Limits Monitor:

• Duty Cycle – Weld Time – K Amps

• Weld Controller Halts with Warning Message if limits are exceeded. Weld

• Controller reads Transformer I.D. Code to verify limits

• +/- Limit K Amps

• Factory Preset Operating Frequency 0.5KC – 2 KC

• Copper Water-cooled IGBT Heat Sink with Temp. Sensor

• Pulsating Heat Time – Cool Time Control

• Upslope – Downslope – Quench – Temper Control

• One Time Squeeze Delay in Repeat Mode

• Weld Heat Stepper

• Weld Pressure Stepper

• Direct Interface to Intertron Interlock Scanner

• Edit Lock via 4 Digit Pass Code for Each Weld Schedule

• Edit Weld Schedule Key Lock for All Weld Schedules

• Intermittent and Continuous Drive Motor Speed Control

• Weld and Forge Air Pressure Regulators

• 00 – 99 PSI or 000 – 682 KPA

• Air Volume Booster 45 CFM or 150 CFM

• Weld Cylinder Pressure Hi – Low Limit Sensor

• Chain Weld Schedules for Special Application Requirements

• Switch Inputs:

• Retraction – 1st and 2nd Stage – Remote Weld – Tip Dress – E. Stop

• Head DN – Key In – Key out for Machines with Key Lock Cylinder

• Heat Time Override Limit Switch in Butt Weld Mode

• Dual Anti-Tie-Down Mode: Momentary – Push and Hold

• Valve Outputs Retractions – Weld – Forge – Water Saver – Key Lock – Clutch/Brake

• RS232 Interface to P.C. prints out Weld Impulse Monitored Time and Current Upload/Download

• Weld Schedules to and from P.C.

• Secondary Weld Current Programming: K Amps or Heat %

• All Time Controls are Programmed in Milliseconds or Cycles

• Weld Schedule 000 allows setup of Initial Default Values and Units of Measure for All Weld Schedules |

|

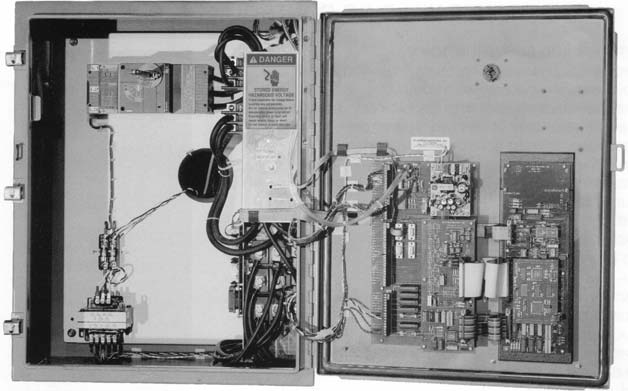

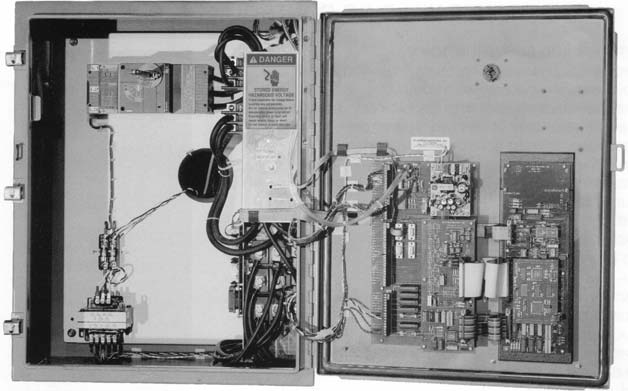

Standard Cabinet Dimensions: 30” h x 24” w x 12” d

ELECTRICAL SPECIFICATIONS

• Input Power 3 Phase 220/240/380/440/480/575 VAC

• 50/60 HZ

• Optional 3 Phase Breaker in Cabinet

• AC Output to Valves 120 VAC, 20 VA per Valve

• DC Output to Forge Valve 24 VDC 0.25 Amps

• Primary Current Driver 200 Amp to 800 Amp in Standard Cabinet

• 1000 Amp to 2000 Amp Driver in HL Cabinet, 12” taller than Standard |

|