Soft Touch Safety Feature for Unitrol Welding Controls

- Protects against PINCH POINT INJURIES with a fully PASSIVE system

- Installs on any type of spot welder

- SAVES MONEY by improving weld QUALITY

Unitrol Soft Touch

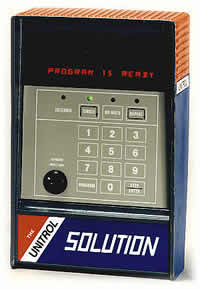

A NEW FUNCTION FOR UNITROL SOLUTION

UNITROL announces a new safety function that is now available on all Unitrol resistance welding controls. This patent pending function keeps the electrode force very low until it is safe to apply full welding force. Existing SOLUTION controls can also be upgraded for this SOFT TOUCH function. The SOFT TOUCH system cannot be installed on any other brand welding control.

HOW IT WORKS: After initiation, electrodes start to close under LOW FORCE. A Unitrol TOUCH SENSOR system decides when the electrodes have closed on or near the metal being welded. If an obstruction is detected prior to closing, the electrodes will go back to the fully opened position. No adjustment of SOFT TOUCH is needed when changing welding force or electrode spacing.

The system is field adjusted with lockable settings (to meet OSHA compliance) so that force between electrodes for the advance portion of the stroke remains low enough to avoid major injury to the operator’s fingers. For press welders, this will even reduce force between electrodes to considerably less than the dead weight of the ram.

FAIL SAFE SYSTEMS:

If the sensor switch is already closed when the welder is being initiated, the electrode will not even start to move, and the display will show which sensor input is closed at that time.

If the sensor wires from the SOFT TOUCH system have become disconnected or are making poor contact, the electrodes will close under low force and then return after a short field-settable delay (1-999 cycles).

WHAT HARDWARE IS NEEDED: To make this system operate, you will have to add a 5-way externally piloted solenoid valve, a shuttle valve, and a precision pressure regulator system to an existing 4-way externally piloted (or direct acting) solenoid valve. Unitrol offers three kits for easy installation:

HEAVY WEIGHT RAMS: This #9181-34W kit is used on:

- PRESS WELDERS that have dead weight (with air disconnected from welder) of over 50 pounds. The kit is factory pre-plumbed for fast installation and includes all necessary components and interconnecting tubing.

LIGHT WEIGHT RAMS: This #9181-34Y kit is used on:

- PRESS WELDERS that have dead weight (with air disconnected from welder) that is less than 50 pounds, or does not drop by it’s own weight.

- ROCKER ARM WELDERS. The kit is factory pre-plumbed for fast installation and includes all necessary components and interconnecting tubing.

LIGHT WEIGHT GRAVITY-DROP RAMS: This #9181-34H kit is used on:

- PRESS WELDERS that have dead weight (with air disconnected from welder) of less than 50 pounds and drops smoothly by gravity. The kit is factory pre-plumbed for fast installation and includes all necessary components and interconnecting tubing.

REDUNDANT SENSOR: You can also add your own proximity switch or LVD system adjusted to close a switch when the electrodes are less than ¼” apart to the system. The SOLUTION will not turn on the high-pressure valve until both metal is detected and the proximity switch has been closed. This is often useful for applications where the parts being welded are not flat prior to the welding process.

KEEPING SPOT WELDER OPERATORS SAFE

By Roger Hirsch, President, Unitrol Electronics Inc.

WHO KNEW THAT PEOPLE WERE GETTING INJURED ON SPOT WELDERS!

I never thought spot welder safety was such a big deal until recently. Here is the story:

We received a panic call from a company that had a large number of our Unitrol SOLUTION resistance welding controls. After two accidents in their resistance welding department within a two-month period of time, OSHA was threatening to close their welding department down if an acceptable way of guarding the welder’s electrodes could not be found.

THE PROBLEM: Because of the parts being spot welded, the welder operators had to hold parts in a way that put their fingers close to the electrodes. They tried to change the fixtures so that a margin of safety was achieved, but that only slowed down production and was not even possible for the majority of parts being welded.

He explained that a safety system had to be installed that did not depend on any operator settings or adjustments. And when electrodes were changed or holders were adjusted to alter the electrode spacing, the safety system had to continue to operate without the need to make adjustments

FIRST IDEA: The first attempt at finding a solution was to use a light curtain to protect the area between the electrodes. However this idea was quickly abandoned when they realized that the operator had to hold and move parts near the electrode and would be in the light curtain zone. Also when jobs were changed and the electrodes adjusted, very fine tuning of the light curtain system would have been required.

SECOND IDEA: They then decided to install a ring guard system. With this type of guard, a wire loop on the end of a rod is set around the top welding electrode. The loop is sent downward at the beginning of each weld before the electrode starts to move. The electrode will not close if the loop stops short of a set distance (as would happen if the loop contacted a finger).

Ring guard systems were installed on six welders and then shown to the OSHA advocate. He said this application of a ring guard would not pass an OSHA inspection. The problem was that a ring guard could be easily defeated by the operator. Also he pointed out that the actual safety value of a ring guard was completely dependent on the mechanical adjustment of the wire ring by the setup person. In other words, the only time it was safe was when the ring was set at the proper height and the operator did not bend or rotate it out of place.

The OSHA advocate told them that they had to find a FULLY PASSIVE SYSTEM.

He explained that a safety system had to be installed that did not depend on any operator settings or adjustments. And when electrodes were changed or holders were adjusted to alter the electrode location, the safety system had to continue to operate without the need to make adjustments.

THE SOLUTION: Unitrol took up the challenge and developed SOFT TOUCH, a fully passive patent-pending system that provides very low electrode force when the area between the electrodes is not safe, and only applies full electrode force when it is safe to do so. This new development was done using electronic sensing rather than mechanical switches or moving parts.

HOW SOFT TOUCH WORKS: SOFT TOUCH is a fully passive fail-safe system that is controlled by the Unitrol SOLUTIONwelding control. Because SOFT TOUCH is part of the control and not just an add-on system, it is fully integrated into the welding sequence. This means that the system works “right out of the box” without the need to wire together and program multiple components.

SEQUENCE: When the foot or hand switch is closed to start a weld

- The welding electrodes close under low force. The unique pneumatic systems designed by Unitrol for this process can counter-balance the weight of the ram on large press welders. Even where the dead-weight of the ram is hundreds of pounds, the electrode force produced will be 40 lbs or less.

- The SOLUTION control checks to see if metal is detected between the electrodes and within a maximum time. This is done from electronic signals inside the welder and does not use any external sensors.

- If metal is not detected within this time, the electrodes open and remain there until the foot or hand switch has been released. At the same time, the SOLUTION display shows that the DETECT TIME has been exceeded.

- If metal is detected within this time, full welding force is applied and the normal welding sequence is completed.

REDUNDENT SYSTEM: If desired, a limit switch can be added to the welder and adjusted to close when the space between the electrodes is less than 1/4”. In this case, the SOLUTION control has to see both that there is metal between the electrodes and that the limit switch has been closed. This is useful where the weld surfaces on parts, such as C-shaped loops, are not touching at the start of a weld sequence and use the electrodes to push them together..

FULLY PASSIVE: There are no operator adjustments. Even if electrode height is changed or welding pressure is adjusted, the SOFT TOUCH system operates without any setting changes. In fact, there is nothing for the operator to adjust. All settings are locked in the cabinet.

THE RESULT: The company installed SOFT TOUCH on one welder, and it cleared the OSHA advocate’s inspection. They eventually installed 22 systems and are back to operating on a 3-shift production schedule.

ADDING SOFT TOUCH TO YOUR WELDER: The SOFT TOUCH system is only available for installation on new and existing Unitrol SOLUTION welding controls. The kit includes a padlockable NEMA-12 enclosure that houses the precision pressure setting components, and special valves that are to be added to the welder’s existing solenoid valve.

Your Unitrol authorized distributor can help you size a SOLUTION control with the SOFT TOUCH feature for any spot welder including PRESS WELDERS, ROCKER ARM WELDERS, and TRANSGUNS.

OSHA RESEARCH FOR SOFT TOUCH CONCEPT

May 2004

Unitrol contacted an OSHA representative and discussed the requirements for pinch point guarding for resistance welders. The operation of the SOFT TOUCH system was also discussed. The OSHA representative recommended the following regulations to cover requirements for this device:

1910.212(a) (general machinery)

Machine guarding

http://www.osha.gov/pls/oshaweb/owalink.query_links?src_doc_type=STANDARDS&src_unique_file=1910_0212&src_anchor_name=1910.212(a)(1)

1910.212(a)(1)

Types of guarding. One or more methods of machine guarding shall be provided to protect the operator and other employees in the machine area from hazards such as those created by point of operation, ingoing nip points, rotating parts, flying chips and sparks. Examples of guarding methods are-barrier guards, two-hand tripping devices, electronic safety devices, etc. Unitrol note:The SOFT TOUCH sensor board is an “electronic safety device” in that it closes an electro-mechanical relay when it electronically senses that the electrodes are closed on the metal part in the work area prior to application of high force.

1910.255(b)(4) (resistance welding machines)

Guarding. All press welding machine operations, where there is a possibility of the operator’s fingers being under the point of operation, shall be effectively guarded by the use of a device such as an electronic eye safety circuit, two hand controls or protection similar to that prescribed for punch press operation, 1910.217.

Unitrol note: The following sections are all that were recommended for this application:

1910.217(c)(3)(iii)

A presence sensing point of operation device shall protect the operator as provided in paragraph (c)(3)(i)(a) of this section, and shall be interlocked into the control circuit to prevent or stop slide motion if the operator’s hand or other part of his body is within the sensing field of the device during the downstroke of the press slide.

Unitrol note: The electrode on the low-force ram becomes the “sensor” in this system. The “downstroke” of the welder, with the Soft Touch system installed, starts when high pressure is applied to the welder ram.

1910.217(c)(3)(iii)(b)

The device may not be used as a tripping means to initiate slide motion. Unitrol note: This Soft Touch circuitry does not initiate any valves. It is only an input into the weld control to indicate that the part being welded has been sensed in between the electrodes.

1910.217(c)(3)(iii)(c)

The device shall be constructed so that a failure within the system does not prevent the normal stopping action from being applied to the press when required, but does prevent the initiation of a successive stroke until the failure is corrected. The failure shall be indicated by the system.

Unitrol note: At the start of each stroke, we check to see if the sensing system is closed. If it is, the sensor stroke is never started, and the control’s display shows the fault. The sensor must be opened before any other action is possible on the welder.